Continuous (Piano) Hinge – Stainless Steel

$55.00 – $295.00

Buy Now, Pay Later options available

- Stainless Steel

- Stainless Pin

Please fill in the fields below with the shipping destination details in order to calculate the shipping cost.

Everything you need to know about the stainless steel continuous piano hinge

The Dunn and Watson stainless steel continuous piano hinge is ideal for a host of applications, including the fabrication of toolboxes, canopies, caravans and camper trailers. So if you need to refit your recreation or work vehicles and you want a lid, window or canopy wall to open and close smoothly or a benchtop to fold up perfectly against a wall, then this piano hinge is the perfect solution.

Made from 304 grade stainless steel, this continuous hinge has excellent corrosion resistance, making it perfect for salty or coastal areas. It’s designed to handle extensive wear and tear and holds up well against the Australian climate, as well as evening the load against both mounted surfaces.

What sizes are available?

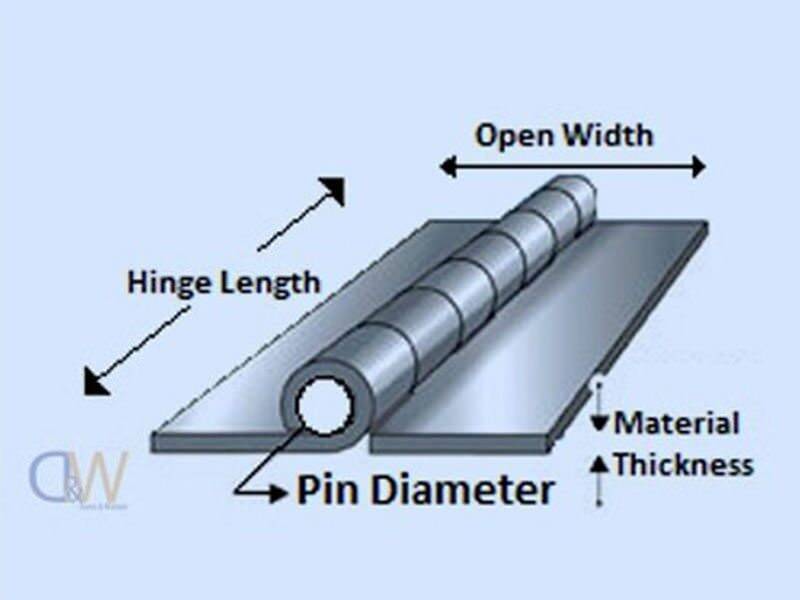

The stainless steel continuous piano hinge is available in a number of sizes, so you shouldn’t have any problems selecting the right one for your project. In fact there are seven different standard sizes with lengths ranging from 1800mm to 2400mm. The open widths range from a small 32mm, right up to 120mm, whilst the pin diameters range from 3.15mm to 8.0mm. As the length of these hinges increases, the thickness of the materials and the pin also increases. So as you increase the length, they become better able to take on larger loads. As you can see, there’s a stainless steel piano hinge for just about every application!

We also provide two other continuous hinges, one made from aluminium with an aluminium pin and the other galvanised with a galvanised pin:

Applications of the continuous piano hinge

The stainless steel continuous piano hinge is made from 304 grade stainless steel and also has a stainless steel pin. This makes this piano hinge ideal for corrosive environments, such as salty regions or coastal areas. Since it’s made from stainless steel, it also looks smart! Some popular applications include the following:

- Windows, hatches and benches of boats and yachts

- Side opening doors of Utes or trucks

- Rear doors of 4WD trailers

- Drop down sides of trailers

- Toolboxes

- Side benches

- Canopy windows

How to select the right size continuous hinge for your project

Making sure that you have the correct size piano hinge for your project is essential, because you definitely don’t want it to be too long or too short. However, you can install multiple hinges one after the other if one hinge is too short. You can also cut the hinges down to size, if they are too long. It’s important to remember that the longer the length of the hinge, the more weight they can support.

So if you have a small lightweight toolbox with a length of 2000mm, for example, it makes sense to select a 2400mm continuous piano hinge and cut off 400mm, rather than using two 1800mm hinges, one of which needs to be cut down significantly to fit the opening. Unless of course, the larger pin size and width of the 2400mm hinges are more suitable for your project. This means that you don’t only need to consider the length of the hinges you need, but also the size of the pin, open width and the thickness of the material, because this also gets larger as the length increases.

Another point to note is that none of these hinges have any holes in them, so you can easily drill through the hinges and install them as needed, making them an easy fix. So simply measure the length of your opening and determine how many hinges you need, then cut them to suit the opening.

If you have any problems deciding which size continuous hinge is right for your project, just give us a call or send us an email and we will help you make the right choice.

Benefits of using a continuous piano hinge

These hinges are ideal for applications where strength, security and durability are a priority. So if you want to fit them to a toolbox, once your box is padlocked shut, these hinges will keep it locked! There’s no way that a thief can pry these hinges away from the mounted surface, so they are ideal for doors, windows and tool boxes that need to be kept locked and secure. Another benefit of these continuous hinges is that they evenly distribute the load down the entire length of the attached surfaces, making them ideal for high load applications.

A continuous piano hinge also provides a seamless look to your project, because there aren’t any gaps between the two mounted surfaces as there would be with butt hinges. This also makes them ideal for added security, because there’s no gaps where a crowbar can fit through to force a window, door, hatch or lid to open. In addition, these continuous hinges help to keep both mounted surfaces perfectly aligned. They also provide a pivot action that remains smooth and even, reducing wear and tear, dissipating any pressure on the mounted surfaces. Finally, they are easy to align correctly and simple to install.

- Increased security

- Extended life span

- More privacy

- Evenly distributed loads

- Perfect alignment of mounted surfaces

- Ideal for corrosive environments

- Reduced wear and tear

High quality Dunn & Watson hinges

All of the Dunn & Watson continuous piano hinges are made in Australian using local materials. Every hinge is identical to the other and each size is consistent and high quality. When you order one or more of our piano hinges, we have a quick delivery service, so you won’t be waiting long for your hinges to arrive!

These hinges are very popular because they have a wide application and are particularly useful for projects where wear and tear or frequent use is a problem. They are designed to reduce the stress along the length of the two mounted surfaces and provide a far more precise alignment than butt hinges, making them the ideal solution for many applications. They can be cut to size, making these piano hinges customisable for many different projects. With a smooth pivot action, these continuous hinges are a very cost effective alternative to more traditional hinges. They are used in a wide range of applications and are easy to install and simple to use.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.